A Comprehensive Research Report on Water-Guided Laser in the Precision Manufacturing Industry

source:Laser Daily

keywords:

Time:2025-09-17

Source: Laser Daily 6th Sep 2025

Abstract

This report conducts a comprehensive and in-depth investigation into the application of water-guided laser technology in the precision manufacturing industry. It begins by elaborating on the fundamental principles, core advantages, and key components of water-guided laser technology. Subsequently, it provides a detailed analysis of its extensive application scenarios in precision manufacturing fields such as semiconductors, aerospace, medical devices, and automotive manufacturing. The report also delves into the core technical challenges, material processing difficulties, equipment and process control issues, and industrialization barriers faced by this technology. It further conducts a systematic study on the market status, competitive landscape, and future development trends. Through the analysis of typical cases, the report demonstrates the significant potential of water-guided laser technology in addressing traditional processing pain points, enhancing product quality, and promoting industrial upgrading. Finally, the report offers an outlook on the future development direction of water-guided laser technology, aiming to provide valuable references for researchers, engineers, and decision-makers in related fields.

Part One: Research on the Basic Technology of Water-Guided Laser

1. Basic Concepts and Definitions of Water-Guided Laser

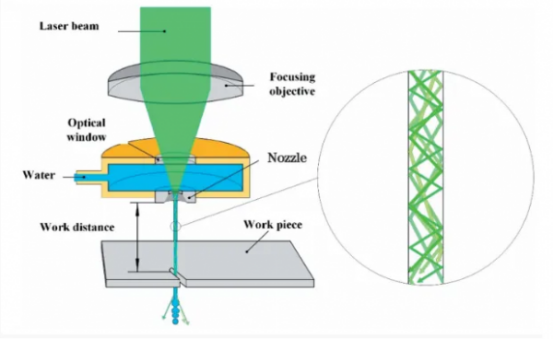

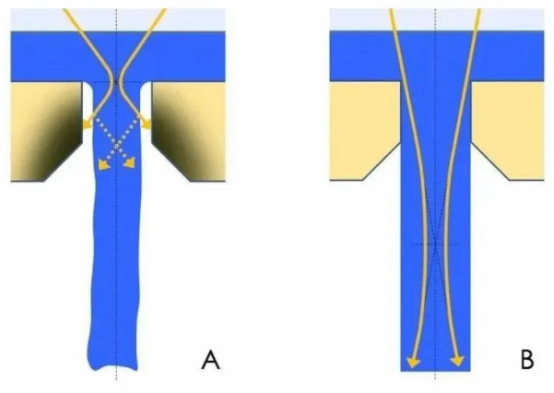

Water-Guided Laser (WGL for short) is a precise processing technology that couples a laser beam into a fine water jet. Its fundamental concept is to use water as a light-conducting medium to transmit laser, similar to the working principle of traditional optical fibers. The core principle is to utilize the difference in refractive index between water (approximately 1.33) and the surrounding air (approximately 1.0), and through the total internal reflection phenomenon, the laser is stably transmitted within the water jet. At the interface between water and air, the laser undergoes total reflection and is guided to the surface of the material to be processed.

Schematic diagram of the working principle of water-guided laser

2. Historical Development of Technology

The development of water-guided laser technology can be traced back to the 19th century. In 1842, Colladon discovered that light could be transmitted along a water jet, laying the theoretical foundation for water-guided laser technology. In 1854, Tyndall further confirmed through experiments the phenomenon of total internal reflection of light in a curved liquid flow. However, it was not until the late 20th century that this technology was truly applied to industrial processing. In 1987, Dot first attempted to combine laser and water jet, creating the concept of the "laser knife". In 1991, Dr. Richerzhagen from the Swiss Federal Institute of Technology conducted in-depth research on the principle of water-guided light and successfully developed water-guided laser processing technology in 1993. In 1997, Synova was established and made commercial improvements to the technology, promoting its wide application in precision manufacturing.

3. Principles of Water-Guided Laser Technology

The working principle of water-guided laser technology can be summarized into four steps: laser coupling, light conduction, energy transfer, and cooling effect. Firstly, a high-power pulsed laser beam is precisely coupled into a fine water jet. Then, based on the principle of total internal reflection, the laser stably transmits within the water jet, similar to the conduction process of light in optical fibers. Next, the laser energy is precisely transferred to the work surface through the water flow, achieving precise material processing. Finally, during the processing, the water jet plays a dual role of cooling and confining the laser beam, effectively reducing the heat-affected zone and improving the processing quality.

4. Advantages of Water-Guided Laser Processing

Compared with traditional processing methods, water-guided laser technology has significant advantages. Firstly, it can achieve ultra-high precision processing at the micron level, meeting the strict requirements of precision manufacturing for dimensional accuracy and surface quality. Secondly, the cooling effect of the water jet significantly reduces the heat-affected zone during the processing, avoiding thermal damage and deformation of the material, and is particularly suitable for processing heat-sensitive materials. In addition, water-guided laser technology has wide material adaptability and can process various hard and brittle materials such as metals, ceramics, composites, and semiconductors. Due to its non-contact processing method, it avoids tool wear and mechanical stress, ensuring excellent surface quality. At the same time, the water jet can effectively remove processing debris, keep the processing area clean, and further improve processing quality and efficiency.

Part Two: Market Status and Development Trends

1. Global Market Size and Growth Forecast

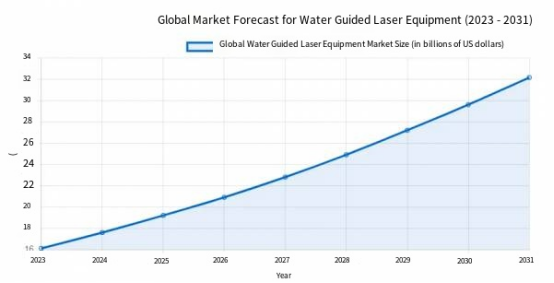

As an emerging precision processing technology, the market size of water-jet guided laser technology is growing rapidly. According to the research data from QYResearch, the global market size of water-jet guided laser processing equipment was approximately 1.759 billion US dollars in 2024 and is expected to reach 3.215 billion US dollars by 2031, with a compound annual growth rate (CAGR) of 9.0% during this period. Among them, the market for precision five-axis water-jet guided laser cutting machines is one of the fastest-growing segments, and it is expected to reach 1.619 billion US dollars by 2031. As the world's largest manufacturing country, China's demand for precision processing technology is increasing day by day, and the water-jet guided laser market is also showing a rapid development trend. In 2024, the market size of water-jet guided laser in China has exceeded 50 million RMB and is expected to maintain a high growth rate in the coming years.

2. Current Status of Industrialization Development

At present, the global water jet laser technology market is mainly dominated by the Swiss company Synova. As the pioneer and leader of water jet laser technology, Synova has a complete technical system and core patents, and its products have been widely applied in the global high-end manufacturing field. In contrast, the domestic water jet laser industry is still in its infancy, and there is still a considerable gap in technical level compared with advanced foreign enterprises. The main domestic enterprises include WetTech Intelligent Manufacturing, Coast, Shanghai Lengchen Technology, etc. Some enterprises assemble and produce domestically by introducing foreign technology, and are also actively engaged in independent research and development and technological innovation. The cooperation between HGLASER and the Swiss Synova has injected new vitality into the development of domestic water jet laser technology.

3. In-depth Analysis of Application Scenarios in the Precision Manufacturing Industry

Water-guided laser technology, with its unique advantages, shows broad application prospects in the precision manufacturing field.

The aerospace field

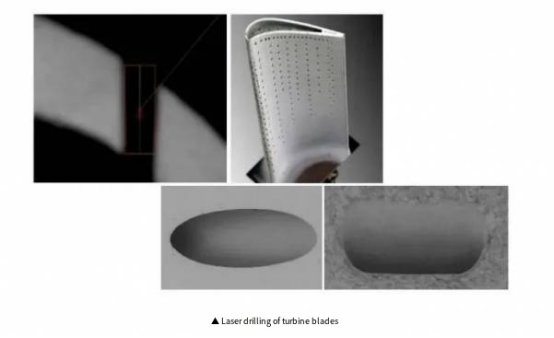

In the processing of cooling holes in aero-engine turbine blades, water-guided laser technology can be used to process complex-shaped holes, avoiding the formation of recast layers and microcracks, and significantly improving cooling efficiency and blade life. In addition, it also has important application value in the cutting of composite materials and the processing of precision parts.

The semiconductor industry

In processes such as silicon wafer cutting and chip packaging, water-guided laser technology can achieve high-precision cutting without thermal damage, ensuring the performance and reliability of chips, and enhancing production efficiency and yield.

Medical device manufacturing

The non-contact and high-precision processing characteristics of water-guided laser technology give it a unique advantage in the manufacturing of medical devices such as surgical instruments, implants, and microfluidic chips, meeting the strict requirements of medical devices for precision, safety, and biocompatibility.

New energy industry

In fields such as lithium battery plate cutting, solar panel processing, and fuel cell component manufacturing, water-guided laser technology can effectively reduce burrs and thermal effects, enhance product consistency and performance, and drive technological upgrades in the new energy industry.

Electronic manufacturing industry

In the processing of LTCC materials, precision circuit board cutting, and electronic component processing, water-guided laser technology can solve the problems such as dimensional effect and large heat-affected zone existing in traditional laser processing, providing an efficient and precise processing solution for the electronics manufacturing industry.

4. Prediction of Technological Development Trends

In the future, water-guided laser technology will develop towards miniaturization, intelligence and multi-functional integration of equipment. With the continuous maturation of technology and the gradual reduction of costs, its application fields will further expand to emerging areas such as biomedical chips, quantum devices and new materials. At the same time, with the continuous improvement of the technological level of domestic enterprises and the enhancement of independent innovation capabilities, the localization process will further accelerate, and the water-guided laser industry will usher in a broader development space.

Part 3: In-depth Analysis of Technical Difficulties and Challenges

1. Core technical challenges

Laser-water jet coupling technology

One of the core challenges in water-guided laser technology is achieving efficient and stable laser-water jet coupling. This requires precise optical design, high-quality laser beams, stable water jets, and a sophisticated alignment control system. Any deviation in these aspects can lead to a decrease in coupling efficiency and an increase in energy loss, thereby affecting the quality and efficiency of the processing.

Stability control of water jet

Obtaining a stable and laminar fine water jet is a prerequisite for achieving high-quality processing. This requires precise control of parameters such as the nozzle's geometry, water pressure, water quality, and temperature. Factors such as nozzle wear, environmental vibration, and impurities in the water can all disrupt the stability of the water jet, leading to a decline in processing accuracy.

Precision nozzle manufacturing technology

The nozzle is the core component of water-guided laser equipment, and its manufacturing accuracy directly determines the quality of the water jet. The aperture, roundness, coaxiality, and inner surface roughness of the nozzle all need to reach micron-level precision, which poses extremely high requirements for ultra-precision processing technology.

Process parameter optimization

The water-guided laser processing involves numerous variables such as laser parameters (power, pulse width, frequency), water jet parameters (pressure, flow rate, diameter), and motion parameters (speed, path), among which there exist complex nonlinear relationships. For different materials and processing requirements, a large number of experiments and data analyses are needed to find the optimal combination of process parameters to achieve the best processing effect.

2. Specific technical challenges in material processing

metal materials

Although water-guided lasers have demonstrated excellent performance in metal processing, when processing different types of metal materials, it is still necessary to optimize the process parameters in accordance with their distinct physical properties (such as reflectivity, thermal conductivity, melting point, etc.). For instance, when processing materials with high reflectivity like copper and aluminum, the issue of low laser absorption rate needs to be addressed; when processing difficult-to-machine materials with high hardness and high melting point such as Hastelloy, a balance between processing efficiency and quality needs to be struck.

Ceramic materials

Ceramic materials are characterized by high hardness and brittleness, which makes them prone to cracking and chipping during processing. Although the "cold processing" feature of water-guided laser can effectively reduce thermal stress, precise control of laser energy and scanning path is still necessary during processing to avoid material damage caused by mechanical stress.

Composite materials

Carbon fiber reinforced polymers (CFRP) and other composite materials have anisotropic characteristics, with significant differences in the physical properties of their matrix and reinforcing phases. During processing, defects such as fiber pull-out, delamination, and matrix carbonization are prone to occur. Although water-guided laser technology can effectively reduce thermal damage, fine-tuning of process parameters is still necessary to achieve precise removal of different component materials.

3. Equipment and Process Control Challenges

Complexity of system integration

The water-guided laser equipment is a complex system integrating laser, high-pressure water, precision machinery, motion control, and sensor detection. To achieve efficient coordination and stable operation among the subsystems, it poses high demands on system integration technology.

Equipment reliability and maintenance

The lifespan and reliability of core components such as nozzles, high-pressure seals, and optical elements directly affect the stable operation of the equipment and the quality of processing. The replacement and adjustment of these precision components require professional technicians and dedicated equipment, resulting in relatively high maintenance costs.

Real-time monitoring and feedback

Real-time monitoring and closed-loop feedback control of the processing procedure are the key to ensuring processing quality and stability. This requires the development of high-speed and high-precision sensing technologies and control algorithms to achieve real-time monitoring and dynamic adjustment of parameters such as water jet status, laser power, and processing morphology.

4. Industrialization barriers

Core technology patent barriers

At present, the core patents of water-guided laser technology are mainly held by a few foreign enterprises such as Synova of Switzerland, which constitutes a relatively high technical barrier and restricts the technological development and market competition of domestic enterprises.

The manufacturing cost of the equipment is high

Water-guided laser equipment involves numerous high-precision components and advanced technologies, with high manufacturing costs. This, to a certain extent, restricts its promotion and application in small and medium-sized enterprises.

Market awareness and talent cultivation

As an emerging technology, the market awareness of water-guided laser still needs to be enhanced. Meanwhile, the shortage of professional talents in related fields also restricts the promotion and application of this technology.

Part Four: Case Studies and Practical Application Analysis

Case One: Machining of Cooling Holes in Aeroengine Turbine Blades

Application Background: Aeroengine turbine blades operate in harsh environments characterized by high temperatures, high pressures, and high rotational speeds. Their performance and lifespan directly impact the overall performance and reliability of the engine. To enhance the high-temperature resistance of turbine blades, it is common to machine a large number of film cooling holes on the blade surface to form a layer of cold gas film, which isolates the blades from direct exposure to high-temperature gases. Traditional machining methods such as electrical discharge machining and conventional laser machining often result in defects like microcracks and recast layers around the holes, which can affect the fatigue performance and service life of the blades.

Water-guided laser solution: Water-guided laser technology, with its unique "cold processing" advantage, offers an ideal solution for the precise processing of cooling holes in turbine blades. By precisely controlling the laser energy and water jet parameters, high-quality, defect-free cooling holes can be machined on the blade surface. Experimental studies have shown that the cooling holes processed by water-guided laser have smooth hole walls, no recast layer and microcracks, and the geometric accuracy consistency of the holes has also been significantly improved. This not only enhances the cooling efficiency and reliability of turbine blades, but also provides technical support for the development of higher-performance aero engines.

Case Two: Semiconductor Wafer Dicing

Application background: With the continuous improvement of chip integration, the precision and quality requirements for wafer dicing are also getting higher and higher. The traditional diamond blade cutting method is prone to edge chipping and cracks at the wafer edge, which affects the yield and performance of the chip. Although traditional laser cutting is fast, its thermal effect is likely to cause thermal damage to the wafer and performance degradation.

Water-guided laser solution: Water-guided laser technology, with its characteristics of no thermal damage and high precision, shows great application potential in the field of semiconductor wafer cutting. Through the cooling and cleaning effects of water jets, thermal damage and debris contamination during the cutting process can be effectively avoided, resulting in high-quality cutting edges. Research shows that wafers cut by water-guided laser have smooth edges without chipping, and the electrical performance and reliability of the chips are also effectively guaranteed. In addition, water-guided laser technology can achieve narrower cutting channels, thereby manufacturing more chips on the same wafer, improving the utilization rate of the wafer and production efficiency.

Case Three: Precision Machining of Medical Devices

Application Background: The manufacturing of medical devices has extremely high requirements for precision, safety, and biocompatibility. Many medical devices such as surgical knives, interventional catheters, and implantable stents all require micron-level precision machining. Traditional machining methods are difficult to meet these demanding requirements and are prone to problems such as burrs and contamination.

Water-guided laser solution: The non-contact, pollution-free, and high-precision processing characteristics of water-guided laser technology make it an ideal choice for the precision processing of medical devices. By precisely controlling the laser beam, it can perform fine cutting, drilling, marking, and other operations on various medical materials, achieving smooth and burr-free processing surfaces. For example, in the manufacturing of heart stents, water-guided laser technology can precisely cut complex mesh structures, ensuring the mechanical properties and biocompatibility of the stents. In the manufacturing of surgical instruments, water-guided laser technology can process extremely sharp cutting edges, improving the accuracy and safety of surgeries.

Although water-guided laser technology still faces some challenges in terms of equipment cost, core technology, and industrialization at present, these problems will be gradually solved with the continuous maturation and innovation of the technology. In the future, with the miniaturization, intelligence and multi-functionality of the equipment, as well as the continuous expansion of application fields, water-guided laser technology will play an increasingly important role in the global precision manufacturing field and create a better future for mankind.

References

Zhihu Column: Principles, Characteristics, Applications and Research Progress of Water-Guided Laser Technology. https://zhuanlan.zhihu.com/p/27771545683

Chinese Optical Journal Network: Mechanism and Research Progress of Water-Guided Laser Microprocessing. https://www.opticsjournal.net/Articles/OJf7751bd6ca07f0/FullText

OE Journal: Experimental Study on Water-Guided Laser Processing of metal Materials. https://www.oejournal.org/oee/article/doi/10.12086/oee.2020.190423

Kuwei Technology: Technical Challenges of Water-Guided Laser Processing. http://www.kwong-tech.com/news/hyzx/878.html

Sina Finance: Sino-foreign joint venture! This laser enterprise's move is "worth watching". https://finance.sina.com.cn/stock/relnews/cn/2025-04-23/doc-ineuerfh6454662.shtml

Sohu: Application of Water-Guided Laser Processing in Semiconductor Manufacturing. https://www.sohu.com/a/815516235_121441097

Zhihu Column: Application and Development Status of Water-Guided Laser Processing Technology. https://zhuanlan.zhihu.com/p/28286025575

4th Collaboration! What Brought the Global Laser Academic Guru to Chinese Univs & Leading Firms?

4th Collaboration! What Brought the Global Laser Academic Guru to Chinese Univs & Leading Firms? DNE Laser Foshan Smart Manufacturing Base Grand Opening: New Brand Image Starts New Journey

DNE Laser Foshan Smart Manufacturing Base Grand Opening: New Brand Image Starts New Journey Live: DMP GBA Expo – Laser Hard Tech Leads Industrial Smart Manufacturing New Wave

Live: DMP GBA Expo – Laser Hard Tech Leads Industrial Smart Manufacturing New Wave Scientists Develop Palm-sized Short-pulse Laser System: Efficiency Increased to 80%

Scientists Develop Palm-sized Short-pulse Laser System: Efficiency Increased to 80% Global LiDAR Giants Engage in Escalating Patent Wars

Global LiDAR Giants Engage in Escalating Patent Wars

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining

Shi Lei (Hipa Tech): Focus on Domestic Substitution, Future Layout in High-End Laser Micromachining Optizone Technology: 17 Years Devoted to Optics – High-Power Optics Mass-Production Pioneer

Optizone Technology: 17 Years Devoted to Optics – High-Power Optics Mass-Production Pioneer Zhuojie Laser: Breaking barriers via tech breakthroughs, aiming to lead high-end light sources

Zhuojie Laser: Breaking barriers via tech breakthroughs, aiming to lead high-end light sources Dr. Sun Linchao: Pioneer and Leader in China's Field of Medical Aesthetic Laser Therapy

Dr. Sun Linchao: Pioneer and Leader in China's Field of Medical Aesthetic Laser Therapy Guo Guangcan, CAS Academician & USTC Professor: Four Decades Chasing Quantum "Light"

more>>

Guo Guangcan, CAS Academician & USTC Professor: Four Decades Chasing Quantum "Light"

more>>